In order to be able to

adhere to QbD specifications of IPM to obtain a mixed end product

where an

«API» homogeneously (concentration deviation <2%) needs

to be mixed in a high viscosty silicon oil

(viscosity over 2 million cps) a RAMAN spectroscopic device was used

to optimize the mixing tools.

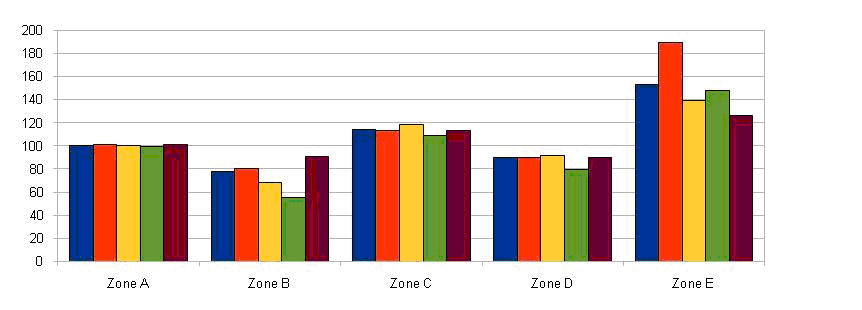

Figure

1: Percentage of label claim API in LSR/API mix at known areas of

poor mixing before ajustments using a Krieger mixer.

The power of real time

analysis was demonstrated during mixing trial work. During the mixing

trials samples were taken from known areas of less efficient mixing:

these are challenge samples. Figure 1 shows the 5 Raman results taken

for each of 5 challenge samples. The RSD was 27% demonstrating poor

mixing.

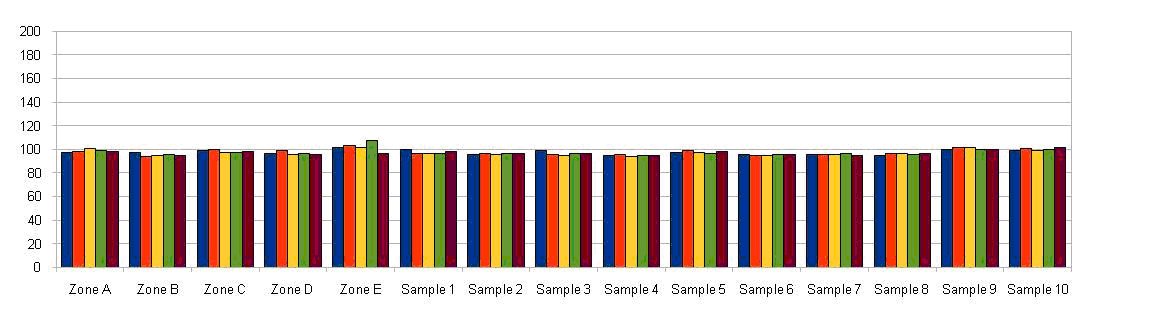

Figure 2 shows the same 5 challenge regions taken after modifications

and an additional period

of mixing: the RSD for the same challenge positions was reduced to

2.5%.

Figure 2:

Percentage of label claim API in LSR/API mix at known areas of poor

mixing and during discharge after ajustments and two periods of mixing

using a krieger mixer.

Krieger

Homepage