Whether your process requires sterile conditions, powder and liquid ingredients need to be introduced under contained conditions or you simply

need a high quality performing mixing & homogenising system under vacuum:

Krieger's platform and building blocks design approach meets your specific needs!

Two design platforms, the Molto Mat and the K-Mix range can be chosen in function of your application. The base platform can be combined

with various building blocks, each with a wide variety of process functions and technical requirements to fine tune your equipment to suit your

exact needs.

Our platform design allows to configure mixing & homogenising equipment ranging from vacuum processing to processing under the most

stringent sterile and toxic conditions. Varous building blocks for CIP and SIP can be chosen from to complete the solution to suit your needs.

A wide choice of mixing tools, high speed dissolvers and homogenisers with different FDA sealing concepts is available.

In addition many interfaces for integration of other processing equipment are avalable, like integration of wett grinding mills, integraton of

contained splitt valves, etc....

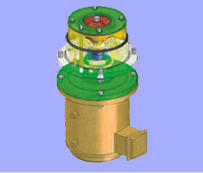

The Krieger CIP/SIP counter rotating gear box integrates various functions - mixing,

homogenising, cleaning, sterilisation and drying - in one single validated piece of

equipment. This famous Krieger development is now a standard building block on the

Molto Mat and can now be combined with the K-Mix platform to achieve the highest

performing CIP/SIP system on the market for the mixing and homogenising system of

your choice.

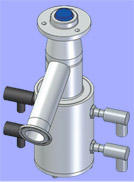

High flow / Low Shear Homogeniser

High flow / High Shear Homogeniser

High speed mixer

CIP / SIP gear box

Bottom inlet / outlet valves